StormHacks 2025: Quadruped Robot

Built a four-legged robot dog in one day at StormHacks 2025 with a Mechatronic Systems Engineering team. I led body assembly and CAD modeling in SolidWorks, designing a modular PLA baseplate for the Arduino, ESP32, PWM servo driver, and battery. MG996R servos powered each leg with quick-swap mounts for fast iteration.

View More Information

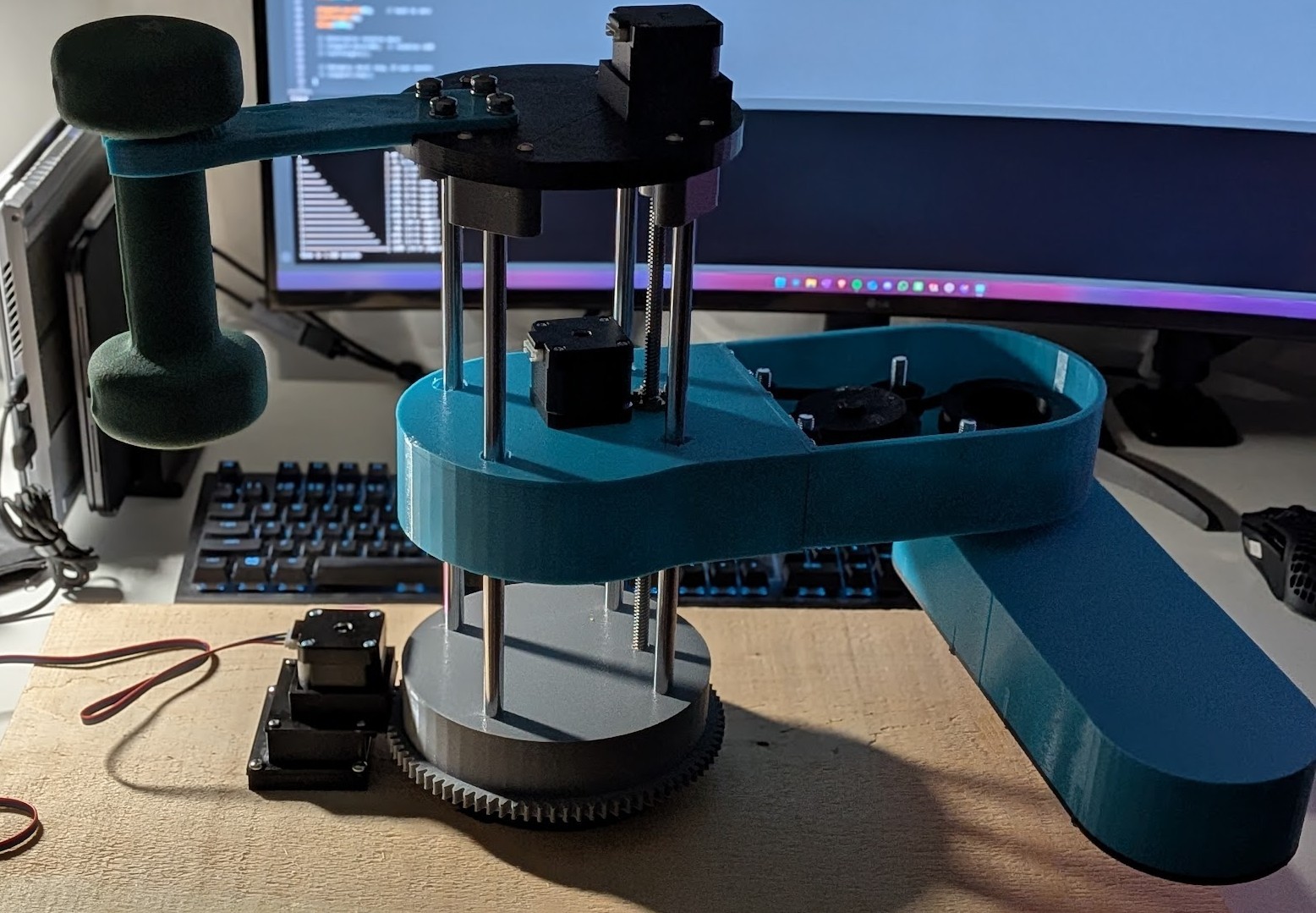

Pick-and-place Robot Arm

Designing a robot arm in SolidWorks and building it using stepper and servo motors. Creating 3D printed gears, GT2 pulleys and structural elements. Two linkages for planar movement by two stepper motors, one stepper motor for z-axis movement + one servo motor for end effector engagement.

View More Information

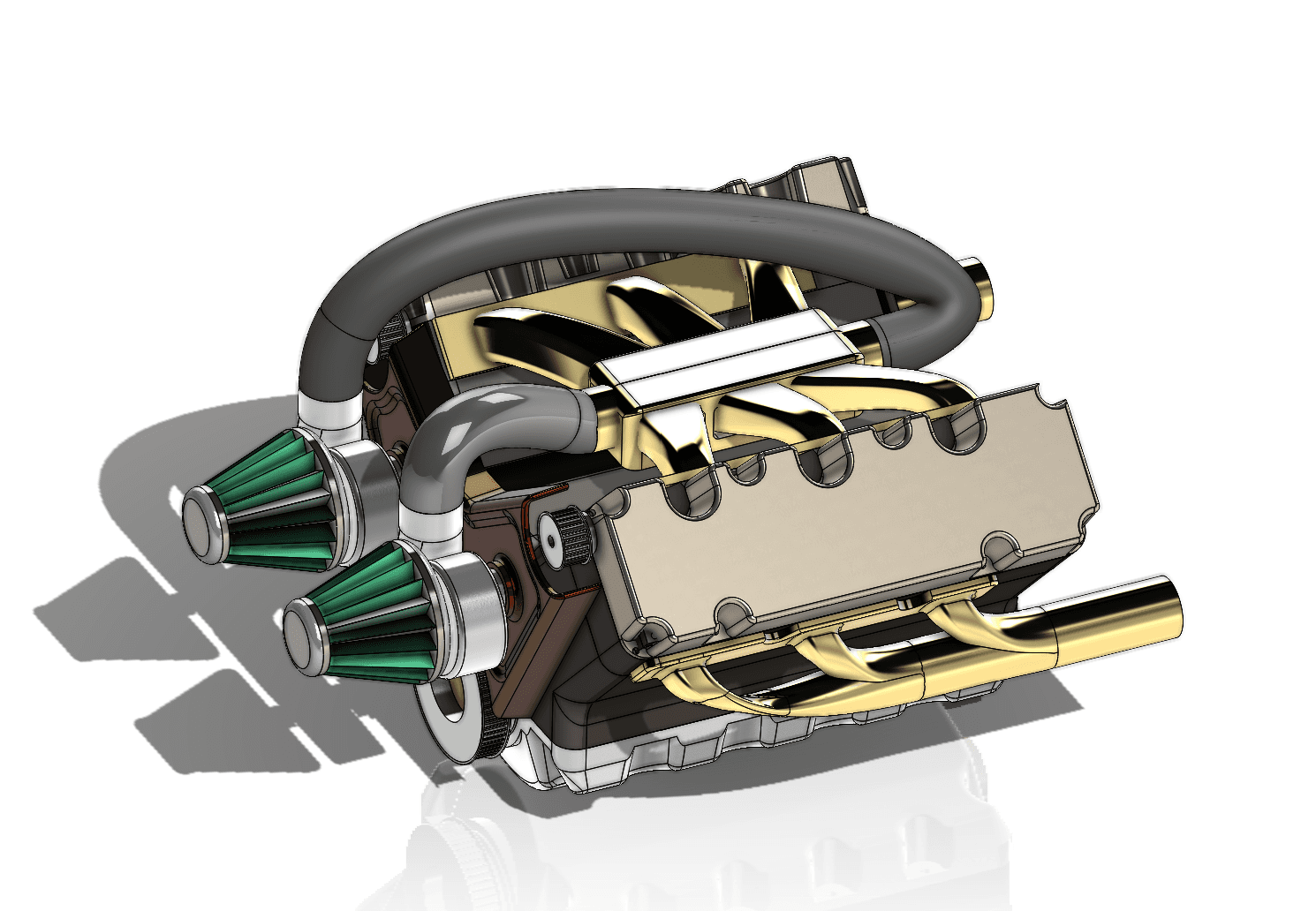

SolidWorks V6 Engine

For this project, I modeled a fully functional V6 engine in SolidWorks. I created each component, including pistons, camshafts, and the exhaust system, and assembled them into a working model that demonstrates engine movement. This project helped me develop advanced CAD skills and a deeper understanding of internal combustion engines.

View More Information

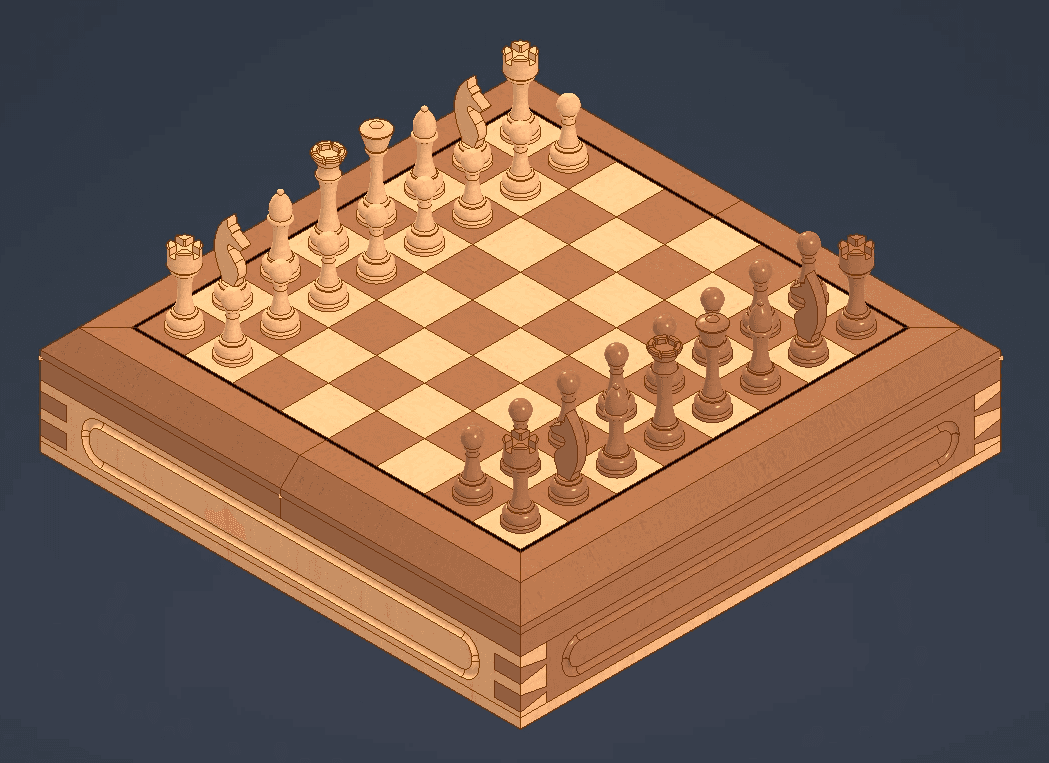

Inventor Chess Set

As part of an Autodesk Inventor Udemy course, I designed a chess set with 25 components and 4 assemblies, including a board and storage box. I applied features such as extrude, revolve, loft, sweep, and fillet, with material assignments and engineering drawings for each piece, and created animations to demonstrate piece movement and box functionality. This project strengthened my Inventor skills and prepared me for design work at BC Hydro.

View More Information

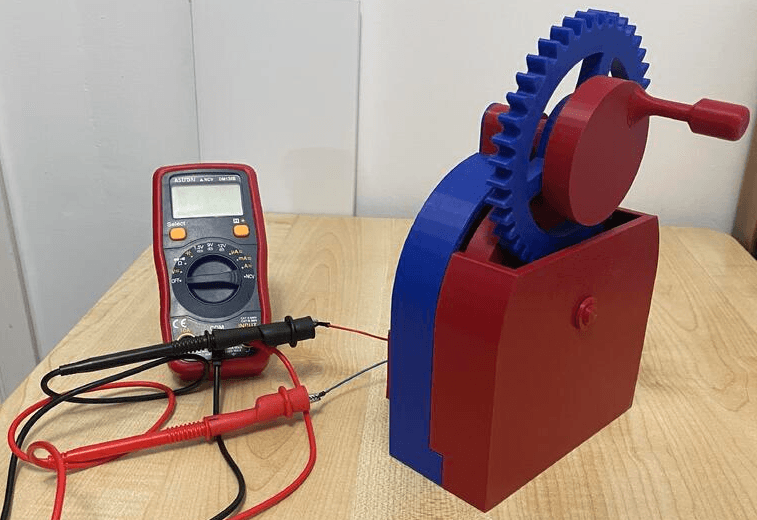

3D Printed Generator

I applied my electric circuits knowledge to design and build a hand-crank generator. Most components were modeled in SolidWorks and analyzed with FEA to ensure they could handle load stresses. I assembled the electrical system by soldering copper coils and a full-bridge rectifier, then tested the circuit with a multimeter. The generator successfully produced a steady 1.42 V DC output.

View More Information

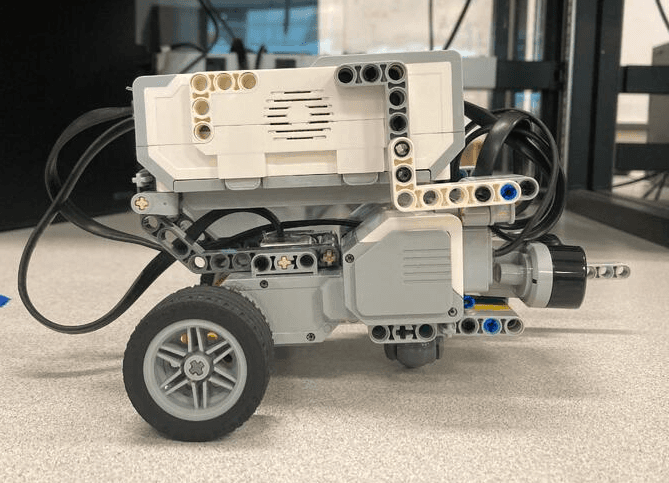

PID Line Tracker

For my Mechatronics Design 1 course at SFU, my team built a high-performance line-tracking robot. I implemented a PID controller to optimize both speed and accuracy, using a color sensor for line detection and an ultrasonic sensor for object avoidance. Our robot took first place in the class competition, earning us an A+ for the project. This experience deepened my skills in control systems, sensor integration, and collaborative engineering.

View More Information

SolidWorks CSWA

The Certified SOLIDWORKS Associate (CSWA) certification demonstrates proficiency in 3D CAD design, including part modeling, assembly creation, and engineering drawing interpretation. The exam tests skills sketching, using features, mass and material properties, and creating accurate models for manufacturing. This certification validates my ability to use SOLIDWORKS to produce professional mechanical designs and assemblies.

Siemens SMSCP Assistant

The Siemens Mechatronic Systems Certification Program (SMSCP) Level 1 certification demonstrates foundational skills in mechatronic systems. Training included programming pick-and-place robots in a small-scale assembly line using TIA Portal, disassembling a 2005 Honda Civic gearbox, and building pneumatic systems both physically and in FluidSIM. I also used Proteus for circuit simulation, worked with relays, and gained hands-on experience with electrical and mechanical components, pneumatic and hydraulic control circuits, and PLC fundamentals. Certification was awarded after passing a three-hour exam.

Basics of Machine Tools

The Basics of Machining course provided training in fundamental skills with manual mills and lathes. I fabricated a phone stand from sheet metal, produced a metal hammer with a lathe-turned base and a milled head, and machined a 1″×1″×1″ cube to within two thousandths of an inch. The course built skills in precision measurement, lathe and milling operations, and machining techniques.

Autodesk Inventor, beginner to expert

Completed Udemy’s 'Complete Guide to Autodesk Inventor from Beginner to Expert' course. Gained experience in part and assembly modeling, weldments, sheet metal design, and creating detailed engineering drawings. Projects included designing a chess box, using the Frame Generator to build tables and trusses, and producing assemblies for manufacturing. The course also covered 3D printing workflows and 3D animation presentations.

WHMIS

The Workplace Hazardous Materials Information System (WHMIS) certification was completed as part of a course requirement. It covers safe handling, storage, and disposal of hazardous products in the workplace, including understanding hazard symbols, safety data sheets, and employer responsibilities under Canadian occupational health and safety regulations.

Basics of CNC Programming & Machining

Completed a hands on certification focused on fundamental CNC machining principles and shop practices. Training covered NC and G code fundamentals, CNC milling and turning CAM workflows using Autodesk Fusion 360, and practical setup and operation of Haas CNC equipment. Gained experience with tool and workpiece probing, machine setup procedures, and safe operation of both 3 axis CNC mills and 2 axis CNC lathes within a laboratory manufacturing environment. Made an aluminum stamp as seen above.